An Expert Perspective from a Food Consultant & Food Factory Consultant

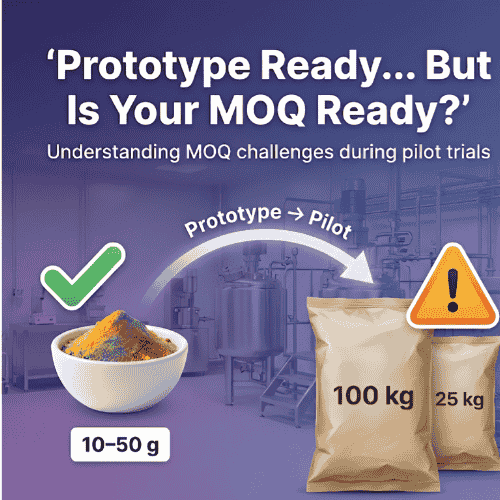

Scaling a food product from prototype to pilot manufacturing is one of the most demanding transitions for any brand. What seems like a simple jump in batch size often becomes complicated due to Minimum Order Quantity (MOQ) requirements from ingredient, packaging and co-packing suppliers.

For early-stage brands, ignoring MOQ realities leads to delays, increased costs, unnecessary wastage and even reformulation. As a Food Consultant, Food Factory Consultant and Food Business Consultant, we regularly guide founders through this critical phase and ensure their product is ready for manufacturing without operational surprises.

This detailed guide explains why MOQ planning matters, what challenges brands face, and how feasibility studies and professional food manufacturing consultancy solve the problem.

Understanding MOQ in Food Manufacturing

In commercial food production, suppliers set minimum order quantities to maintain consistency, efficiency and supply-chain reliability.

Common MOQ examples include:

Basic ingredients: 25–50 kg sacks

Flavours, stabilisers, colours: 5–25 kg drums

Nutraceutical and premium inputs: high MOQs with long lead times

Packaging materials: 5,000–20,000 printed units

Co-packer minimum run sizes: 100–500 kg depending on product category

These numbers are very different from R&D requirements, where prototypes use only a few grams.

Why MOQ Planning Is Essential for Scaling Your Product

1. Controls Cost and Prevents Overspending

Without planning, founders end up purchasing far more material than required for a pilot batch. This increases working capital pressure and limits cash availability for marketing or distribution.

2. Ensures Availability of All Inputs for Pilot Trials

Pilot manufacturing can start only when every raw material, packaging SKU, and processing input meets the supplier’s MOQ. Any one missing item can delay production.

3. Reduces Wastage and Storage Inefficiency

High-MOQ items with short shelf life can expire before commercial production begins.

4. Strengthens FSSAI Compliance & Documentation

Certified raw materials, batch traceability and proper supplier documentation are mandatory. MOQ-ready planning ensures compliant materials are procured.

5. Improves Supply-Chain Predictability

Understanding MOQs early helps build accurate manufacturing timelines and inventory plans.

Key Challenges Brands Face Without MOQ Planning

Suppliers refusing to provide smaller packs

Long lead times for functional or premium ingredients

High printing MOQs creating packaging bottlenecks

Co-packers rejecting non-traceable samples

Cost escalation due to unused raw materials

Frequent reformulations due to unavailable MOQ-friendly alternatives

These challenges directly impact the feasibility, cost, and scalability of the product.

A Strategic MOQ Framework Designed by Food Consultants

As a professional Food Business Consultant and Food Factory Consultant, we follow a structured approach to make products manufacturing-ready.

1. Complete Ingredient & Packaging Mapping

Standard pack sizes

MOQ for each input

Supplier certification

Shelf-life & handling requirements

Lead time assessment

2. Feasibility Study for Scale-Up

Our feasibility studies include:

Cost modeling for pilot and commercial batches

MOQ-sensitive formulation evaluation

Supply-chain risk identification

Pilot plant capacity alignment

Working capital estimation

3. Optimised Formulation for Lower MOQs

Where needed, we help modify formulations using:

Alternative suppliers

Concentrated inputs

Multi-functional ingredients

Raw materials with flexible MOQs

4. Packaging Strategy for Pilot Trials

To avoid high printing MOQs:

Use generic pouches

Adopt sticker or sleeve-based branding

Switch to MOQ-flexible packaging formats

5. Vendor Alignment & Procurement Planning

We coordinate with raw material vendors, packaging suppliers and co-packers to secure MOQ-compliant supplies.

6. FSSAI Compliance & Documentation

A plant-ready material list includes:

CoA

MSDS

Allergen declarations

Manufacturing licences

Food-grade certifications

This ensures pilot batches pass inspections effortlessly.

How Food Plant Setup Consultancy Supports Scale-Up

A Food Plant Setup team bridges the gap between R&D and commercial production by offering:

Equipment selection and line design

Batch size standardisation

Production loss estimation

Process flow development

On-site supervision during pilot trials

This helps founders avoid bottlenecks related to equipment capability and process consistency.

When Is the Best Time to Start MOQ Planning?

Immediately after your prototype is approved.

Starting early ensures:

Conclusion: MOQ Determines Whether Your Prototype Becomes a Product

Successful food brands treat MOQ as a strategic element of product development. When combined with a structured feasibility study, expert food consultancy and strong supplier alignment, MOQ readiness becomes a competitive advantage