IQF Plant Design, Frozen Food Processing & Cold Storage Consulting

Turnkey Engineering & Strategic Consultancy for the Frozen Food Industry

We specialize in Frozen Ready-to-Eat (RTE) Plant Setup, Cold Storage Design and Consulting, IQF Plant Designing and Consulting, and complete RTE Manufacturing Consulting services. From product ideation to full-scale plant commissioning, we deliver end-to-end solutions for frozen meals and RTE food products. Our expertise includes recipe standardization, process optimization, automation planning, contract manufacturing support, and turnkey plant setup. We ensure FSSAI compliance, efficient cold chain and cold storage integration, scalable IQF and RTE production systems, and adherence to global food safety and quality standards — helping brands build successful Frozen Ready-to-Eat manufacturing businesses in India and international markets.

We Help Entrepreneurs Avoid the Costliest Mistakes in Frozen Food Manufacturing

✨Right IQF Line Design — Tailored to Product, Capacity & Freezing Speed

✨Cold Room Engineering Experts — Ideal Insulation, Cooling & Layout Plan

✨Trusted Machinery Vendor Selection — Avoid Costly and Wrong Purchases

✨End-to-End Plant Setup: Processing, Packaging, Storage & Cold Chain

Next-Gen Frozen Product Innovation & Consulting

We help brands build future-ready frozen food products that match modern consumer expectations of convenience, nutrition, and quality. From concept ideation to full-scale commercialization, our team blends technology, food science, and industry strategy to create frozen products that excel in a competitive market.

New Product Development (NPD)

Our food technologists are experts in freeze–thaw stability. We reformulate products to withstand crystallization, storage, and reheating stresses. This includes selecting the right modified starches to prevent syneresis in sauces and using cryoprotectants to maintain protein texture and integrity.

Turnkey Plant Setup & Engineering (Greenfield & Brownfield)

We streamline the setup of frozen food facilities, from greenfield planning to fully operational plants. Our process begins with site evaluation, including soil load-bearing checks for heavy refrigeration equipment and water quality analysis for processing needs. We then create hygienic zoning–based architectural layouts that ensure efficient production flow and eliminate cross-contamination risks from raw material entry to finished goods dispatch.

Regulatory Compliance & Food Safety Infrastructure

We provide complete regulatory and food safety guidance to ensure your frozen food facility is audit-ready from day one. Our services include FSSC 22000 system implementation, BRCGS Food Safety certification support, PRP development, and detailed HACCP planning aligned with global standards. We integrate food safety into the plant’s physical design—specifying hygienic zoning, seamless epoxy flooring, coved wall junctions, and IP69K-rated washdown fixtures to eliminate pathogen harborage points, including Listeria species.

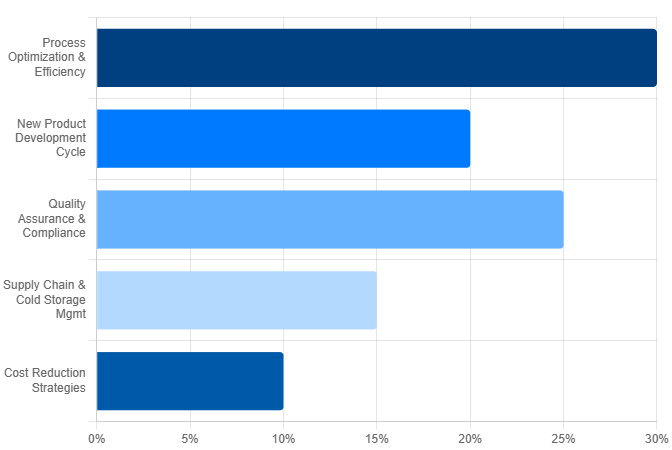

How We Drive Your Success

Our consultancy focuses on five critical pillars of frozen food processing. We bring deep, specialized expertise to each phase of your operation.

Our Expertise

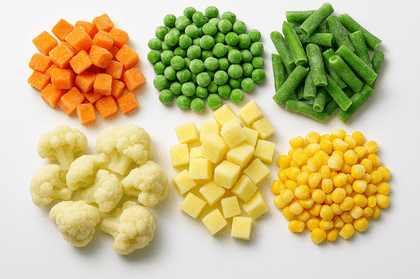

New Product Development (Frozen RTE & IQF)

We develop commercially viable frozen snacks, meals, parathas, momos, fries, vegetables, meat and IQF products. Our team handles recipe design, freeze–thaw stability, texture optimisation and cost engineering so your frozen products perform well in large-scale production and home preparation

Frozen Food Plant Feasibility Studies

Detailed feasibility for frozen and RTE manufacturing units, including product mix strategy, capacity planning, CAPEX/OPEX estimation, utility loads, ROI analysis and location assessment. We help you validate whether your frozen food project is profitable and scalable before you invest.

2D/3D Layout for Frozen & RTE Plants

We design hygienic, audit-ready layouts in 2D and 3D, with clear raw-to-cooked segregation, IQF line integration, cold rooms, blast freezers and packing areas. Our layouts follow hygienic zoning and global best practices to support smooth workflow and food safety.

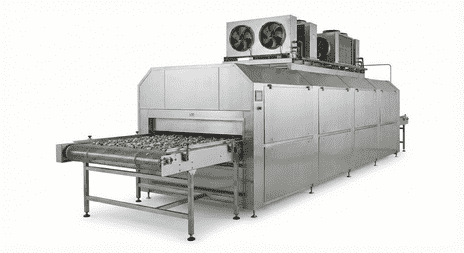

IQF & Frozen Food Machinery Selection & Setup

Expert support in selecting IQF freezers, blast freezers, coating/battering lines, forming machines, fryers, packing machines and refrigeration systems. We compare vendors, specifications and running costs, then support procurement, installation and commissioning for a reliable frozen food lin

Raw Material & Freeze-Stable Ingredient Sourcing

Strategic sourcing of vegetables, meats, coatings, crumbs, stabilisers, modified starches, cryoprotectants and packaging suitable for frozen and IQF products. We focus on consistency, supply security and cost so your frozen RTE range stays stable and profitable.

Food Safety, FSSC/BRC & Cold Chain Compliance

End-to-end support for FSSC 22000, BRCGS and HACCP implementation in frozen food plants. We align processes, documentation and infrastructure—epoxy floors, coved junctions, washable panels, IP-rated fixtures—with global food safety norms and integrate robust cold chain and cold room design for safe storage and distribution

Our Frozen Product Creations

Discover Our RTE Creations

At Prowessbuzz, every Frozen and Ready-to-Eat product we create is designed to make meals effortless, wholesome, and satisfying. Using premium ingredients and developed with care, our offerings bring together convenience, quality, and innovation in every bite.

From hearty meal bowls to smart snacking solutions, our Frozen & RTE range is designed for every mood and every hunger moment. Whether you’re enjoying a favourite classic or trying a newly crafted recipe, you can trust that each creation reflects our passion for food excellence.

Explore our collection – a showcase of Frozen Foods and Ready-to-Eat meals that simplify your day, elevate everyday eating, and make every meal moment special.

-

Parathas & Flatbreads

Tawa paratha, lacha paratha, stuffed parathas.

-

Indian Frozen Snacks

Samosa, kachori, patties, momos, spring rolls, cutlets, nuggets.

-

FlavorBakery & Dough-Based Frozen Foodsed Water & Infused Drinks

Pizza bases, puff dough, chapati, frozen dough products.

-

IQF Vegetables

Green peas, sweet corn, beans, carrots, mix veg, okra

-

IQF Ready Ingredients

Cooked grains (rice, millets), pasta, blanched vegetables.

-

Frozen Storage Rooms (-18°C)

Bulk frozen stock storage.

-

Blast Freezers / Spiral Freezers

Rapid temperature drop for food safety & quality retentio

-

IQF Freezers (air-blast / fluidized bed)

single-piece rapid freeze.

-

Reefer vehicles

refrigerated trucks for chilled (0–4°C) and frozen (-18°C) transport.

Our Consulting Deliverables

Take Away Enterpries Feasibility and Plant Set up

Take Away Enterpries Feasibility and Plant Set upA fully automatic Frozen RTE facility with 14,000 sq.ft. area, featuring paratha/tawa lines, samosa & patty production, and a dedicated non-veg processing section—designed with complete freezing flow, hygiene zoning, and cold chain integration.

14,000 Sq.Ft Plot Vallary Agro Bank Loan/Sunsidy/Plant Set Up

Vallary Agro Bank Loan/Sunsidy/Plant Set UpWe provided complete support for plant setup, bank loan processing, and subsidy documentation for a 5,000 sq.ft. frozen food facility. Our services covered layout design, machinery planning, compliance, and end-to-end project execution.

5000 Sq.Ft Plot Fujiyama Solar Feasibility /Detailed Project Report

Fujiyama Solar Feasibility /Detailed Project ReportWe prepared a complete Feasibility Study & Frozen RTE Project Report for Fujiyama Solar, covering market analysis, capacity planning, machinery selection, financials, and bank-ready documentation for setting up a scalable frozen food unit.

40.000 Sq.Ft Plot Leela Instant Foods Loan and Subsidy

Leela Instant Foods Loan and SubsidyWe assisted Leela Instant Foods with complete bank loan processing and subsidy documentation, including project preparation, financial planning, compliance support, and end-to-end guidance for securing approvals for their food manufacturing unit.

40.000 Sq.Ft Plot

Our Turnkey/EPCC Projects

Success Stories

Copyright © 2025 ProwessBuzz

Powered by ProwessBuzz

Frozen Food Consulatnt in Pune

Frozen Food Consulatnt in Mumbai

Frozen Food Consulatnt in India