Integrated Turnkey Solutions for Food & Beverage Manufacturing in India

Complete Food & Beverage Plant Setup Under One Roof

Engineering Excellence in Food Manufacturing Plant Development

- Market demand analysis and product positioning

- Competitive landscape and pricing benchmarks

- Capacity planning aligned with market size

- Commercial feasibility assessment

- Preparation of bankable Detailed Project Report

- Financial projections, IRR & break-even analysis

- Alignment with state and central government scheme

- Documentation support for subsidies and funding

Product and SKU selection strategy

Process flow development and validation

Technology and processing method selection

Pilot trials and process standardisation

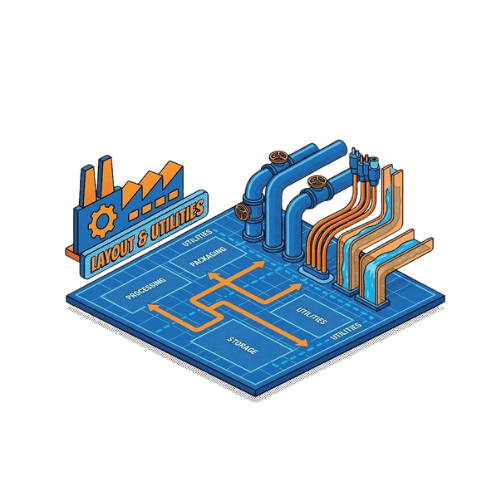

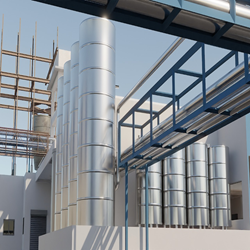

- Factory layout planning (material & manpower flow)

- Utilities design: power, steam, water, air, refrigeration

- Hygiene zoning and GMP-compliant infrastructure

- Provision for future capacity expansion

- Equipment specification and line configuration

- Machinery vendor evaluation and comparison

- Capital cost optimisation and budgeting

- Project scheduling and engineering coordination

- FSSAI-compliant plant and process design support

- Pollution control and statutory approvals coordination

- Factory licensing and regulatory documentation

- Pre-audit compliance checks

Food Processing Categories

End-to-end product segments across food manufacturing

Milk and Dairy

Beverages

Bakery

Confectionery

Breakfast Cereals

Frozen Foods

Sauces & Dips

Spices & Seasonings

RTE

We'd Love To Hear From You

contact us

You take the first step

we handle the rest with expert food development & consulting

FAQ

Food plant set-up services cover the complete journey from market research and feasibility to plant commissioning. This includes business planning, process and technology selection, plant layout and utilities design, machinery selection, regulatory readiness, installation support, and trial runs.

No. Machinery is only one part of a food plant. Proper planning of utilities, manpower flow, hygiene zoning, compliance requirements, product flexibility, and future expansion is equally important for smooth operations and long-term performanc

Market research helps understand demand, competition, pricing, and capacity requirements. Without market validation, plants may be over-sized, under-utilised, or misaligned with actual market needs.

A Govt. & Bankable DPR is a structured document used for bank funding and government schemes. It includes project cost, financial projections, profitability analysis, and alignment with applicable subsidies and schemes

Plant commissioning includes installation verification, utility integration, trial production runs, process stabilisation, and performance checks. The goal is to ensure the plant is ready for regular commercial operations.